HOW TO OPERATE MY PNEUMATIC NAILER SAFELY

Read these five safety tips for nail guns, then make safety a state of mind

Pneumatic tools are great productivity enhancers. They are easy to operate and fun to use. But just when users start to get comfortable with them is when accidents are most likely to occur.

At SENCO, we offer free jobsite safety seminars as a service to contractors and their teams. There is also no shortage of YouTube videos and educational resources online demonstrating how to operate nailers safely. However, SENCO believes that safety is more than a class or a list of tips. It’s a habit and state of mind.

From our perspective and long experience, here are five things to always keep top of mind if you want to stay safe on the job site.

Study Before You Shoot

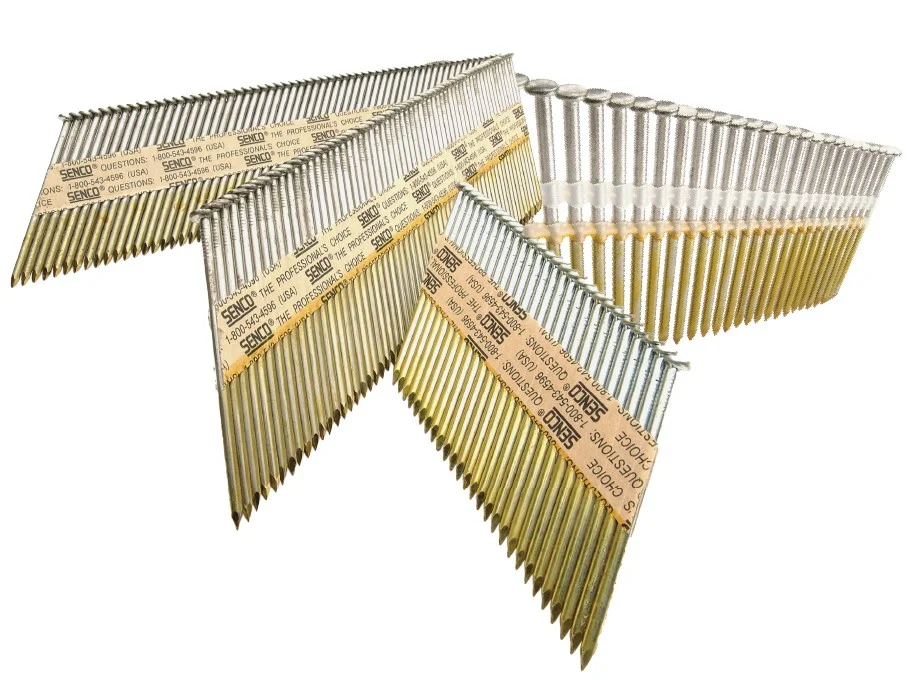

Respecting your tools starts with a solid working knowledge of how they operate. Before you use any tool, take the time to read through the operator’s manual. Familiarize yourself with the tool’s key features, especially things like trigger mechanisms, how to load fasteners and how you should handle air hoses. For hands-on training, ask an experienced user, your supervisor, or a SENCO job site representative.

Put on Your Personal Protective Equipment (PPE)

Before you start working, make sure you’re wearing proper safety glasses. Wood and nail fragments are not the only danger. Dust and debris from the jobsite can be blown around by the exhaust from a pneumatic nailer. Also, if your site requires safety shoes, hard hats, hearing protection or other safety equipment, be sure you’re using them.

Check Your Compressor’s Air Pressure and Drain Regularly

With pneumatic tools, the source of power – air – may be delivered at varying pressures and flows. If the pressure/flow exceeds the manufacturer’s rating stamped on the tool, it can deliver too much torque or other excessive force, which the bumper and other internal components are not designed to handle. In extreme cases, there is a risk of the tool bursting. Before you start working, adjust the air pressure regulator to the manufacturer’s rating.

The air from the compressor also needs to be dry to prevent corrosion and the breakdown of lubricants inside your tool. Water is a byproduct of compressing air. The humidity in the air condenses inside the tank as the air cools after being heated up by the friction from the compression process. This moisture can make its way out of the tank and into the air line. To stop this and keep your tools safe, the tank needs to be drained regularly.

Learn more about choosing the right air compressor.

Watch Where You Point; Keep Fingers off Triggers; When Not in Use, Unplug

There are certain precautions that should be second-nature. Always keep your tool pointed down when not in use. Keep your finger off the trigger when not firing. And disconnect from the compressor when leaving your tool unattended, moving up and down a ladder or stairs, passing it to a coworker, or clearing jammed nails. Also, be aware of what is behind or under your work surface and keep your hands clear of these areas when operating the tool, as a fastener could inadvertently pass through or protrude from the material.

Additionally, keep your off hand at least one foot away from the tip of the nailer. Nails can deflect off of knots, fasteners and other items embedded in the wood. Many jobsite hand injuries are the result of nail deflections, which send the tip of the nail back out toward the user.

Don’t Tamper with Safety Features

Last but not least, you should never alter triggers or safety features on your pneumatic tools. This includes things like removing the spring from the safety contact tip or tying down or taping the trigger so it doesn’t need to be pressed. Make it your daily routine to ensure triggers and safety elements can move freely and all screws and caps are tightly fastened.

Get more safety tips from this video featuring Cincinnati’s Hall-of-Fame catcher Johnny Bench.