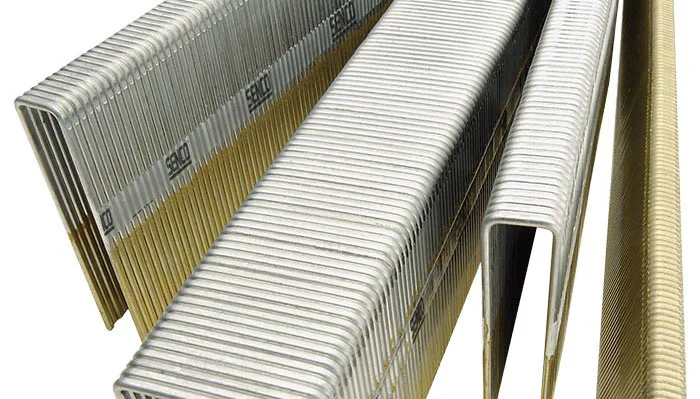

Anatomy of a Staple

It’s difficult to imagine a fastener more versatile than the staple. There’s one for every project, from fine upholstery to subflooring installation. With so much variety, it’s essential to choose the right staple for your job, considering the differences in crown, gauge, point, coatings and more. Read on to learn about these workhorse fasteners and find the perfect one for your next project.

Crowning achievement

The major difference in staples is the length of the crown, that strip of metal that bridges the staple’s two legs. Crown measurements typically range from 3/16” for projects like molding or trim, where the staple shouldn’t be noticeable, to 1” when visibility isn’t an issue and a heavy-duty hold is needed, such as installation of wire lathing or roofing shingles.

Get the gauge right

The thicker the gauge of wire, the more tensile strength of the staple. But stronger isn’t always better — it depends on the project at hand. Staple gauge falls into three categories: fine wire, medium wire and heavy wire. Here’s how they break down by project:

- Fine wire staples range from 20-22 gauge. These staples are ideal for upholstery projects, cabinets, fine wood trim, batten strips, picture frame fitting, wood baskets, plastic parts, molding and furniture assembly.

- At 18-19 gauge, medium wire staples can be used for heavier upholstery, cabinet assembly, paneling, trim, sheathing, underlayment, siding and soffits.

- Heavy wire staples are the strongest, ranging from 15-17 gauge. Use them for sheathing, furniture framing, subflooring, roofing and roof decking, wire lathe, foam insulation board, framing, and framing of crates, pallets and boxes.

Point it out

Depending on the materials involved in your project and their characteristics — density, thickness and wood grain, for example — staple point is a key consideration. SENCO offers the following points in a variety of metals, finishes and gauges:

| Point Type | Materials | Ideal for | Notes | Applications |

| Chisel | Wood | Grainy wood, soft wood | Legs stay parallel | Bedding, butt joints, cabinets, casebacks, composite roofing, corrugated containers, crate and box assembly, decking, door and window units, drawers, engineered and hardwood floors, felt, fencing, foam insulation board, furniture/cabinet frames, furring, house wrap, insulation, insulation sheathing, lathing, lattice, packaging, pallets, roofing, roofing felt, screening, set-up boxes, sheathing, shoes, soffits, subflooring, underlayment, upholstery and vapor barriers |

| Divergent | Metal, wood | Hard wood | Legs twist to hold | Butt joints, cabinets, casebacks, composite roofing, corrugated containers, drawers, foam insulation board, furniture/cabinet frames, house wrap, lattice, roofing felt, sheathing, soffits, underlayment and upholstery |

| Cross cut chisel | Wood | Grainy wood, soft wood | Legs stay parallel | Cabinets, casebacks, drawers, insulation sheathing, lattice, soffits, underlayment and upholstery |

| Outside chisel | Metal, wood | Grainy wood, soft wood | Legs clinch inward | Butt joints, composite roofing, corrugated containers, foam insulation board, furniture/cabinets, house wrap, roofing felt and sheathing |

| Blunt | Metal, wood | Tough, grainy wood; light sheet metal | Legs stay parallel | Cabinets, drawers, laminated hardwood flooring and lattice |

Finish strong

SENCO offers staples in a variety of wire finishes to suit your project, including bright basic, flash galvanized, class 1 galvanized, and stainless steel (type 304). For added benefit, choose staples with Sencote, a specially formulated glue applied to the lower half of the staple. As you drive the staple, the glue melts, acting as a lubricant to allow for an easier drive into the work surface. Sencote then re-hardens to bond the fastener to the material, typically wood, for a stronger hold.

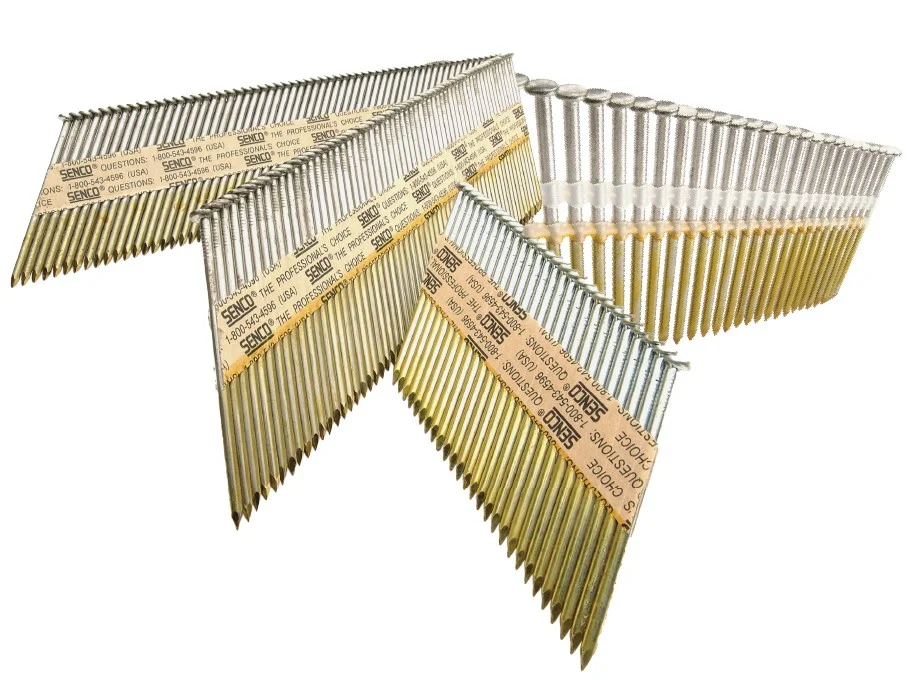

Holding it all together

How your staples are collated ― glue or tape — is a matter of preference. Glued staples offer a stronger hold. Since the glue covers the entire surface of the staple, it acts as a bonding agent when you drive the staple into the substrate material.

Tape is a bit more expensive but offers several added benefits. They’re more flexible, leading to fewer broken strips. This is optimal if you plan to store your staples in a tool pouch and helps the staples avoid breaking if you drop them onto a hard surface. Tape also allows for lower sheer values, providing the tool with more energy to drive into tough substrates.

With so many options, staples help in most any job, and no matter which job you’re tackling, SENCO manufactures the staples you need. Find your local SENCO dealer at https://www.senco.com/find-a-dealer/.