Innovation

Innovation Powered by People

At SENCO, our mission is simple — make hard work easier. We do so by listening to and learning from the men and

women who use our nailers, staplers and screw drivers every day. The needs of our customers drive innovation at every level, from minor

product improvements to breakthrough new technologies.

MADE TO LAST

A dedicated team of engineers, designers and product managers bring every SENCO tool to life using the best components and highest standards. SENCO’s quality control team torture tests nailers and staplers every day to make sure the SENCO products you buy work flawlessly out of the box. That’s why SENCO tools work harder, last longer and make your job easier.

U.S. Manufacturing

SENCO manufactures many of its nails and staples in our Cincinnati, Ohio facility. It may seem old-fashioned, but making fasteners in the USA — then inspecting, measuring and testing them on-site — is critical for quality control.

MADE TO SUCCEED

SENCO’s manufacturing facility on Broadwell Road in Cincinnati is the company’s global headquarters, a million-dollar investment in USA-based collaboration and innovation from parent company KYOCERA.

Recent Product Innovations

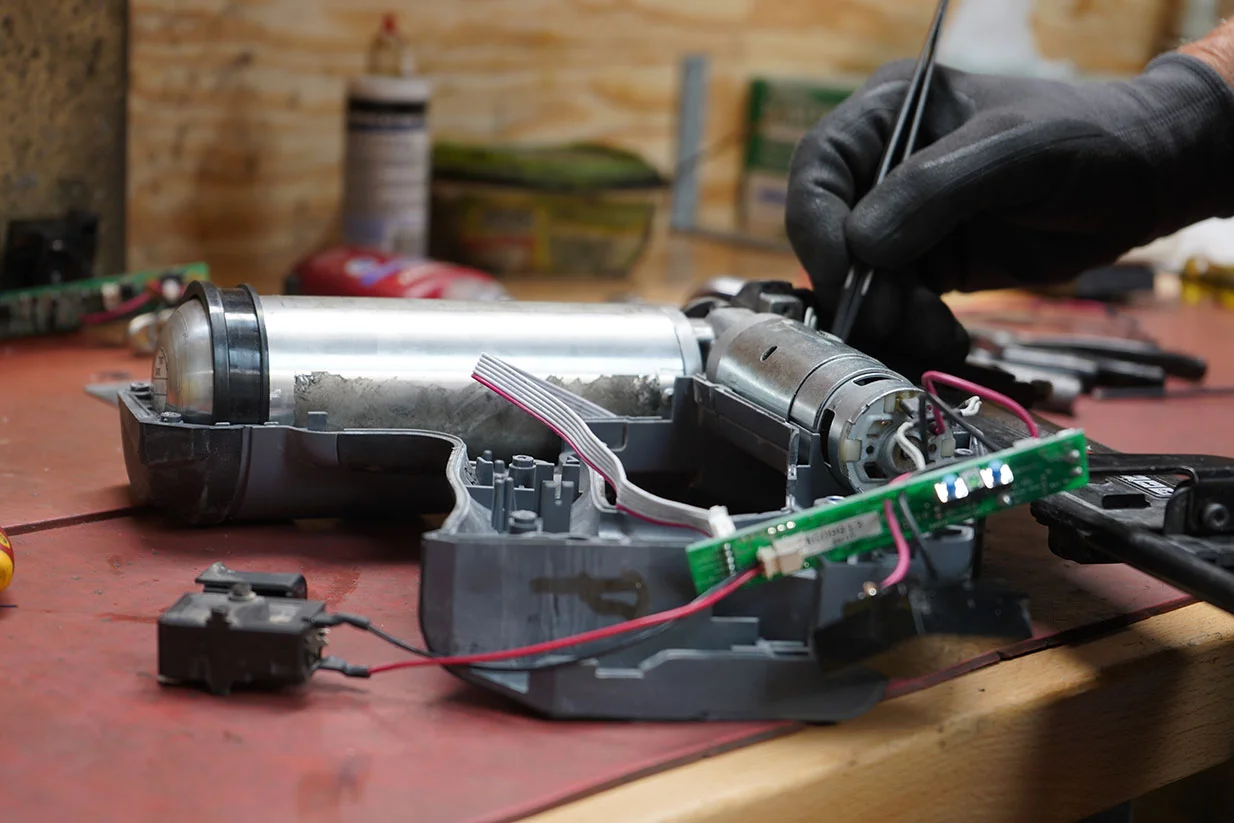

CORDLESS PNEUMATICS

SENCO’s groundbreaking, proprietary FUSION™ technology relies on a permanently sealed air chamber and a battery-powered motor that recompresses the air over and over again. While other cordless technologies use slow mechanical flywheels or expensive gas cartridges to drive nails, FUSION™ tools feel and perform just like their pneumatic counterparts.

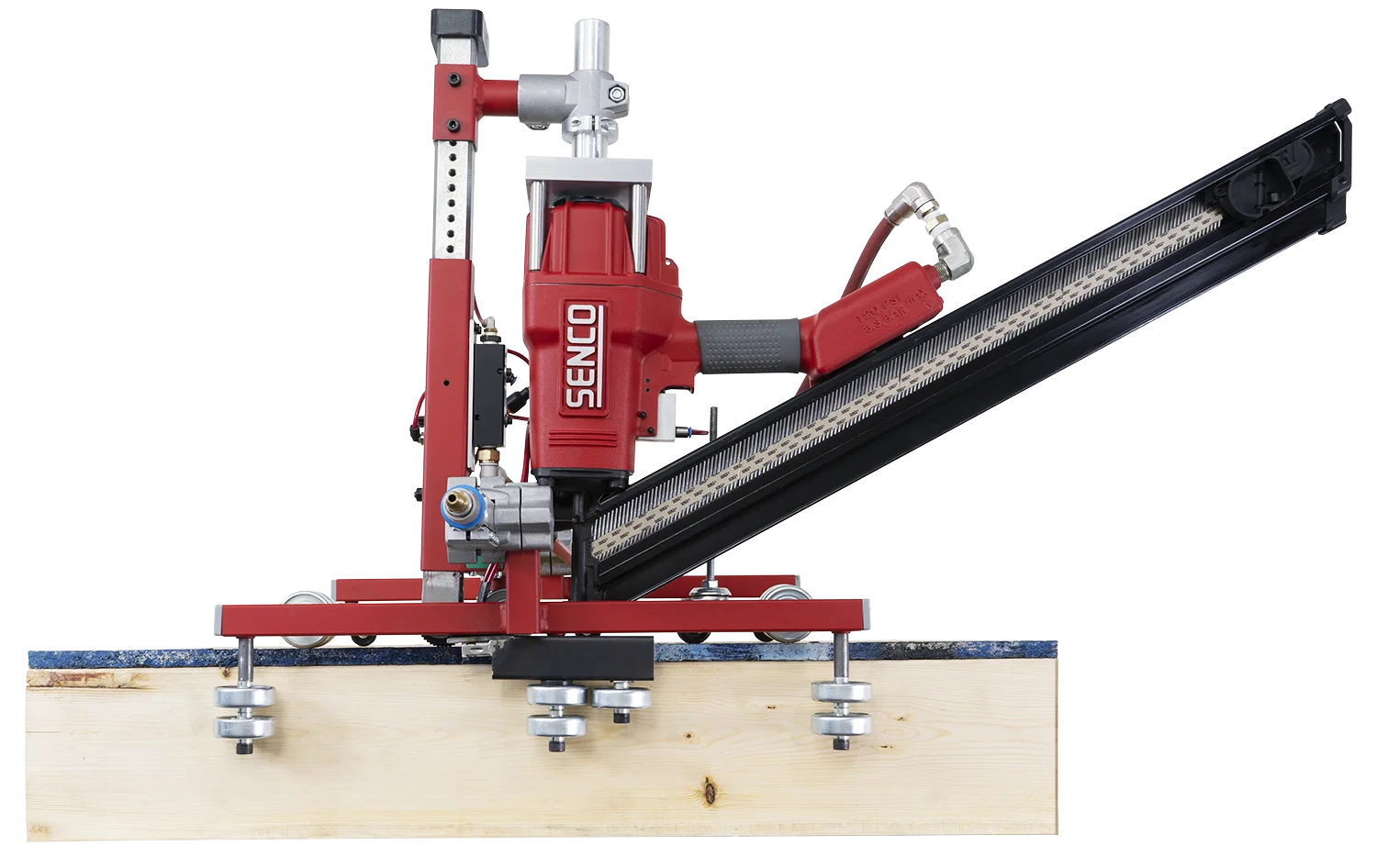

INTEGRATED AUTO-FEED SCREW DRIVERS

SENCO created the first all-in-one auto feed screw system with the launch of DURASPIN™. Featuring the corner-fit feed system, which drives into tight spaces other drivers can’t reach, and a new feed-on-return drive system that improves precision, DURASPIN™ boosts productivity by up to 30 percent.

MAINTENANCE-FREE NAILERS

SENCO’s proprietary NEVERLUBE® technology virtually eliminates routine tool maintenance. Internal components include a unique graphite composite that acts as a dry lubricant and self-lubricating O-rings that won’t dry out. NEVERLUBE® tools don’t need to be oiled and never need to be repacked with grease like other oilless tools.

IMPROVED NAIL TECHNOLOGY

SENCOTE is a specially formulated nail coating that reduces friction for easier drives. The friction melts the coating inside the wood — when it cools it acts as a bonding agent, increasing holding power. SENCO also created the popular DA style finish nail, ideal for nailers with angled magazines that are more maneuverable in tight spaces.

FUTURE-FACING FASTENING

SENCO nailers and DURASPIN systems can be used in mass-production settings where automation is key. SENCO tools and technologies can be incorporated into automated framing and screwing tables that build walls and structures with unmatched speed and precision on a massive scale.