Nailing it Right: Choosing Between Clipped-Head and Full Round Head Nails for Framing

Introduction

In the world of construction, the choice of fasteners plays a pivotal role in determining the strength and durability of the final structure. When it comes to framing, the two most popular options are clipped-head and full round head nails. In this guide, we’ll delve into the characteristics of each to help you make an informed decision based on your specific framing needs.

Throughout this guide, we’ll remind you to check your local building codes. However, generally model codes specify nails by length and by shank diameter, not by the type of nail head. For more about the anatomy of a fastener, check out our blog post on the topic.

Clipped-Head Nails: Streamlined and Efficient

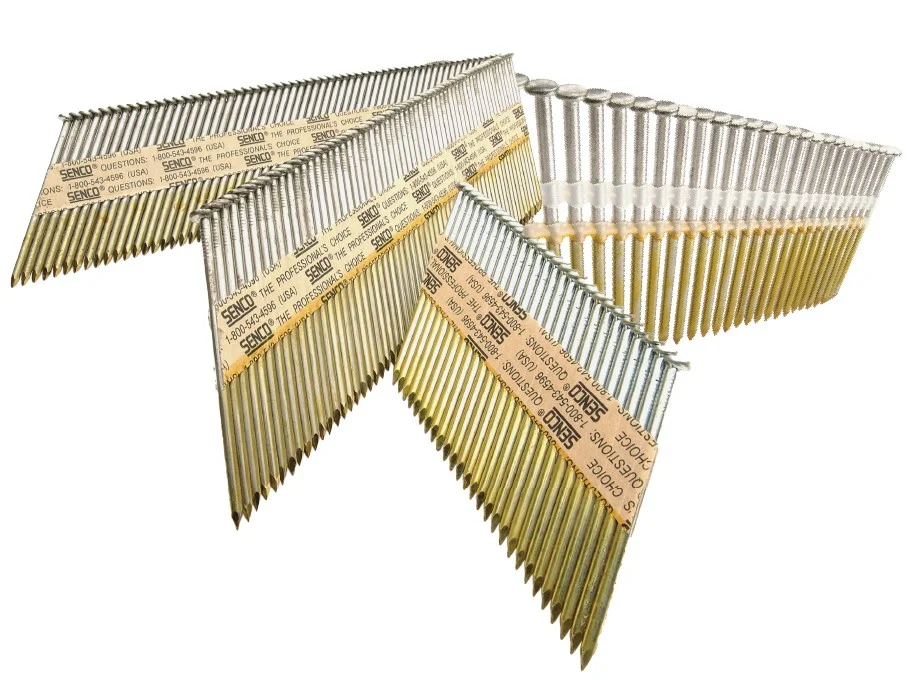

Clipped-head nails have a distinct advantage in terms of efficiency and cost-effectiveness. One key feature of clipped-head nails is their clipped D-shaped head, which allows for a closer placement of nails without sacrificing holding power. This design minimizes the space between nails, ensuring a neat and compact arrangement in the framing assembly. Clipped-head nails are collated at a steeper angle than round-head nails which allows for a greater quantity of nails in a collated strip meaning fewer reloads. This design feature also improves the working clearance (the angle between the gun and the work). Cumulatively, this results in increased productivity on the job site. This efficiency is particularly beneficial in large-scale framing projects where speed is of the essence.

Clipped-head nails are often the choice for framing, sheathing, subflooring, and roofing because the clipped head design allows for closer placement of nails, which can be advantageous in terms of increasing structural integrity and reducing material waste. Make sure to check your local building codes prior to starting a project.

Full Round Head Nails: Maximum Holding Power and Structural Integrity

Full round head nails, on the other hand, are recognized by some building inspectors for their holding power and enhanced structural integrity. It’s important to note that there is no evidence that round head nails provide greater strength or withdrawal resistance than clipped-head nails. The rounded head provides a larger surface area, which some inspectors believe lessens the likelihood of overdriving.

Full round head nails are often the choice for framing, decking, siding installation, fencing, and heavy-duty carpentry. The broader head of full round head nails makes them suitable for applications where enhanced holding power is desired. The head design offers a sturdy connection that helps withstand the elements and the forces that outdoor structures like pergolas, gazebos, playhouses, or fences are subject to. Make sure to check your local building codes prior to starting a project.

Factors to Consider

Building Codes: Check local building codes and regulations to ensure compliance with the type of nails you intend to use. For the current industrial refence for evaluating pneumatic nails, check out the ICC ESR-1539.

Project Scale: Consider the scale of your project. For large-scale projects where speed and efficiency are paramount, clipped-head nails may be the preferred choice. However, for smaller-scale projects exposed to the elements, full round head nails may be more suitable.

Structural Requirements: Assess the specific structural requirements of your framing project.

Pneumatic Nailer: Clipped-head and round head nails are not interchangeable. Make sure you know what type of nail fits your tool. Unsure where to start with nailers? Our nailer guide found here can help.

Conclusion

The choice between clipped-head and full round head nails for framing ultimately depends on the specific requirements of your project. If the nails are properly driven, there is no proved performance difference between the two types of nail heads. Proper spacing of the nails is also essential for performance, regardless of head type. By understanding the strengths of each type of nail, you can confidently select the fastener that best suits your framing needs, ensuring a solid and resilient structure that stands the test of time. And, as always, make sure to check your local building codes prior to starting a project.